JPMA Award-winning product from last several decades

Search is available for JPMA Award-winning product from last several decades

- The number of available

- Records 1-10 of 202

Grand Prix

2019

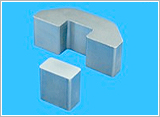

Sintering of disconnect parts

- FINE SINTER CO., LTD.

- TOYOTA MOTOR CORPORATION

- Compaction of ratchet shape with large steps and shape with thin and tall wall was enabled by the improvement of raw material powder and the structure of the compaction tools. The heat treatment ensuring the demanded performance of the waved ball groove was realized by introduction of a laser quenching. Realization of components with highly complex and difficult configuration was highly rated. Conventional PM methods did not accomplish such shapes, but this development in mass production indicates the evolution of Near Net Shape PM compaction technology. Further market expansion of PM by the replacement from other competitive manufacturing processes.

2009

Development of high density and low loss powder magnetic core (HDMC) for reactor in hybrid vehicles

- TOYOTA MOTOR CORPORATION

- Daido Steel Co., Ltd.

- TOYOTA CENTRAL R&D LABS., INS.

- The fulfillment of high magnetic properties by using overall and new technology like special powder shape and new coating technology, the real contribution to new trend pro-environment car and the expectation of wide range of development in future were evaluated.

2004

Development of high-strength Fe-Cu-C sintered steel

- DIAMET CORPORATION

- (Mitsubishi Materials Corporation)

- It was highly appraised that they developed material having the same high-strength as diffusion alloyed powder material by focusing attention to the wettability of copper and iron and adding microelement to Fe-Cu-C material, which is most popular sintered material.

New Design

2023

Practical Application of High Frequency & High Strength Reactor Core

- FINE SINTER CO., LTD.

- Daido Steel Co., Ltd.

- The product was highly appreciated for its ability to reduce the product size by approximately 30% and the unit volume by 13% by developing a new material that overcomes conventional issues and significantly improving its properties. The product was also highly evaluated for its efforts to reduce product cost by approximately 30% through keeping improvement throughout the manufacturing process. This product is expected to be used more widely in electric systems, which are expected to continue to increase in the future.

Development of high-precision parts for new mechanism semi-active suspension

- FINE SINTER CO., LTD.

- Using advanced technology, the complex and high precision assembled parts that are difficult to achieve with competing manufacturing methods, were highly evaluated for meeting strict functional requirements and keeping cost control. This product is expected to continue to be in demand even as the electrification of vehicles progresses, and the technology is expected to be applied to similar parts.

Oil-impregnated bearing unit for CPAP equipment that achieves low sliding loss at high speeds

- Porite Corporation

- The product was highly appreciated for meeting user requests by integrating various technologies as well as the sintered seal cap: the medium relief shape, dimples, optimizing choice of material and impregnated oil. In addition, the market is expected to expand in the future as it has been adopted in new equipment in the medical industry and is a technology that contributes highly to society.

Development of Long/complex Shape Rotor and Slide for Variable Displacement Vane Pumps

- SUMITOMO ELECTRIC INDUSTRIES, LTD.

- The development of a new technology that double-shrink-fits the side core with high stress concentration into the die, the realization of a long/complex shaped product with high precision, and the use of multiple reference points in compaction tool design, are recognized as creative breakthrough for solving the problems. This development is expected to expand capability of PM in the precision of large and long items.

2022

Net shape manufacturing of complex multi-level shaped parking parts with two-pcs simultaneous compacting

- SUMITOMO ELECTRIC INDUSTRIES, LTD.

- The new ideas of compaction in upside down and simultaneous 2 pieces to avoid seizure supported by optimization of compaction tool with 3D design enabled the perfect net shape, which is highly appreciated. Cost reduction of 50% was achieved by eliminating machining and the simultaneous two-piece compaction increased the cost competitiveness of PM against other manufacturing method, which is expected to increase PM market.

Mass production of high accuracy and thin-wall product for electric VVT

- FINE SINTER CO., LTD.

- Achievement in high dimensional tolerance of the component having irregular configuration and thin sections which need hardening by exploiting CAE analysis was highly appreciated. The technology which solved the PM's difficult issue and the application in the electric VVT system are considered to increase the potential of PM.

Planetary Brazed Carriers for MT with Improved Endurance Fatigue Strength

- SUMITOMO ELECTRIC INDUSTRIES, LTD.

- By changing the design from conventional way to the new way which does not use step for elimination of rotation while increasing the bonding interface area and by removing volume in gear sections, the customer's demands of strength and cost were satisfied, which was appreciated. This development showed the PM's ability of solution in design flexibility, reliability of quality and improvement of bonding strength to the customer. It is expected to promote the sinter-brazing technology in e-axle of EV etc.